Remanufacturing and product life extension

Image credit: ThisisEngineering RAEng on Unsplash

Image credit: ThisisEngineering RAEng on Unsplash

“I manufacture it, I make a loss. I remanufacture it, I break even. Then I start making money. That’s completely different, isn’t it?”

Description

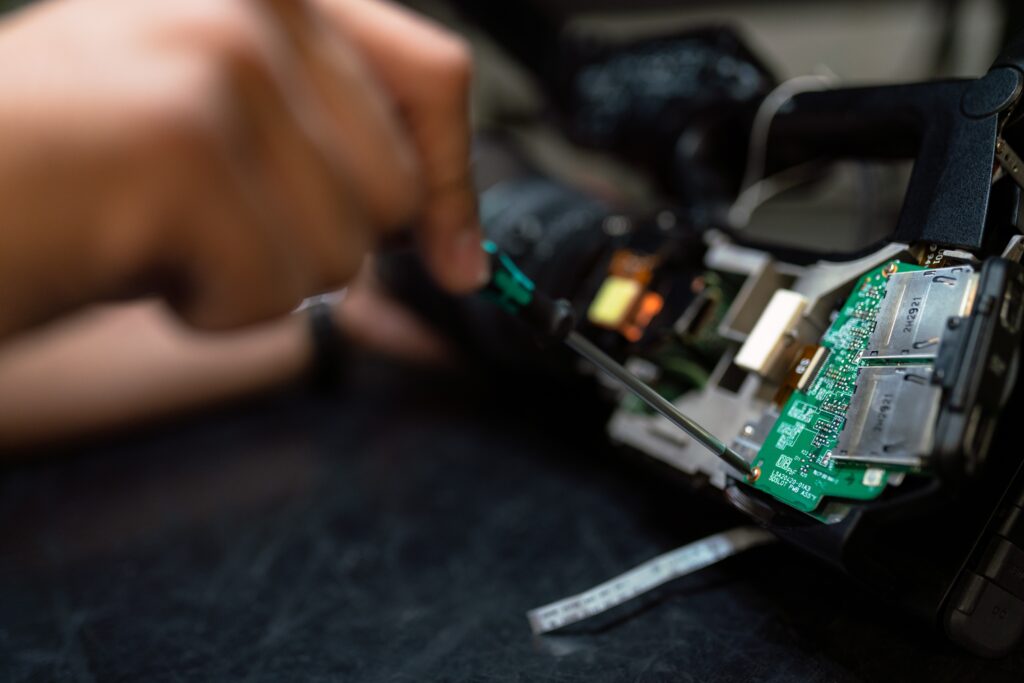

(26:50) “For circular or green manufacturing, they get a bit excited about more recycling. Well, notice it’s near the bottom of the scale. It’s not the first option. I went a little bit higher, with remanufacturing. What is remanufacturing? It’s not repaired, it’s not refurbished, it’s not pimped, it’s not resprayed. It’s not on eBay. It’s a product that’s gone through a manufacturing process, a remanufacturing process, and that goes through lots of steps and stages. It’s in a box, as good or better than new, with a warranty, and you can’t tell the difference. You would hold the remanufactured product, the original equipment manufactured product, and play with it and look at smell it and touch it, and you can’t tell which is which. But the timescales are a lot longer. What you’re used to is how short can I make the production process? How quickly can I sell it, invoice and get the cash? Now you’ve got to rethink how long do I put money into the development? I manufacture it, I make a loss. I remanufacture it, I break even. Then I start making money. That’s the business model.”

Relevance

The benefits of the remanufacturing process are numerous, giving each product a full new life cycle and saving the hundreds of steps it would take to create the same product from scratch. Benefits include: Conservation of Materials, Reduced Energy Consumption, Reduced Waste, Reduced Costs & Lower Prices, and Jobs Created (Remanufacturing supports more than 450,000 jobs world-wide)

Learn more

Vision

EIT Manufacturing vision for the future of Manufacturing in Europe in 2030, called ‘Fixing Our Future

Enablers

Enablers for future change and actions to make the vision, as described in Fixing Our Future, a reali

Signals

A knowledge library of over 100 signals of change, as examples of emerging manifestations towards the

About the project

Learn more about the background, the process and the people and the contributors behind this project.