AI Image Recognition for Vehicle Components

Image credit: Garett Mizunaka on Unsplash

Image credit: Garett Mizunaka on Unsplash

Turning old into new: A second life for vehicle components

Description

A large number of used car parts end up in the scrap yard every year. It is more resource-efficient than recycling if alternators, starters and other parts are repaired and put back into circulation. This reduces the amount of waste, cuts the carbon footprint and extends the life of the parts.

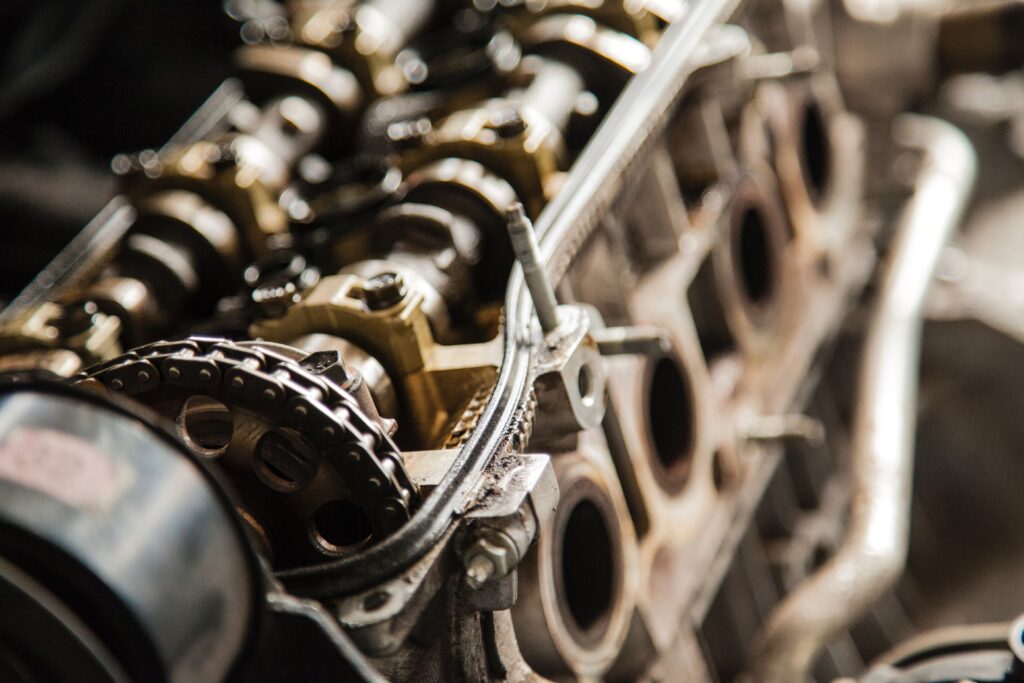

Clearly identifying and assessing vehicle components is one key challenge in the remanufacturing process; part numbers as the only visually reliable feature are no longer legible, scratched, painted over, or type plates have fallen off. Up to now, this task has been carried out manually by specialists under considerable time pressure. If the worker sorts it out by mistake, it is purely recycled. In order to increase the reuse rate, the Fraunhofer Institute for Production Systems and Design Technology IPK is developing an AI-based assistance system to be able to identify used parts without QR or barcodes in an image-based and partially automated way. The system supports sorting and reading so that more used components can be remanufactured.

Relevance

Remanufacturing can become a key component in meeting the Paris climate targets and on the way to a circular economy. According to a study by the VDI Centre for Resource Efficiency, up to 80% of manufacturing costs can be saved by remanufacturing used parts and up to 90% of material consumption can be reduced.

Learn more

Vision

EIT Manufacturing vision for the future of Manufacturing in Europe in 2030, called ‘Fixing Our Future

Enablers

Enablers for future change and actions to make the vision, as described in Fixing Our Future, a reali

Signals

A knowledge library of over 100 signals of change, as examples of emerging manifestations towards the

About the project

Learn more about the background, the process and the people and the contributors behind this project.