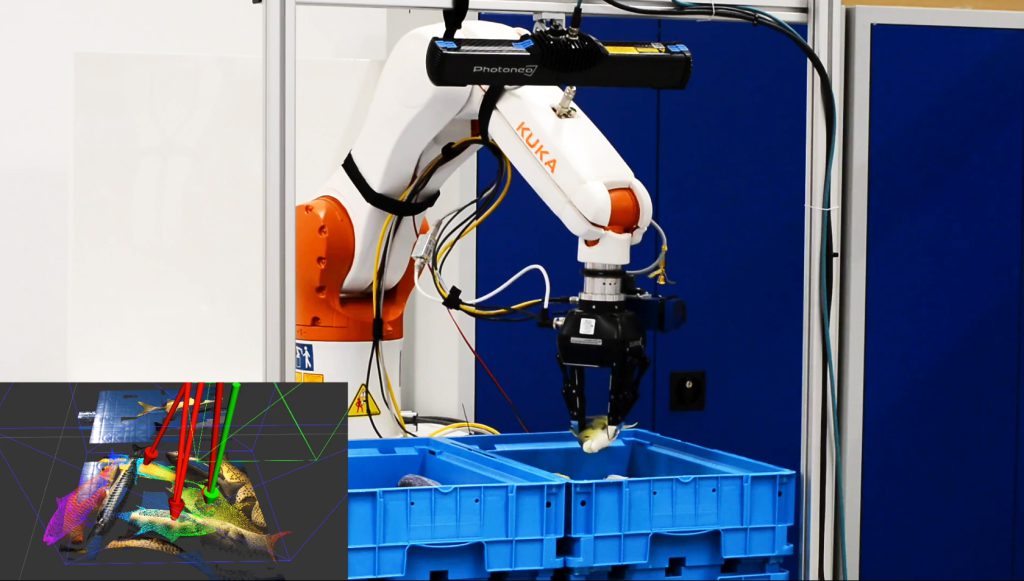

Next Generation Fresh Fish Picking System and Spectral Quality Control

The projects develops Human-Robot Collaborative (HRC) solution to perform autonomous fresh fish picking with spectral quality control in retail manufacturing. The solution addresses various material handling and assembly problems common to many different manufacturing domains.

Spectral, 100% quality control is a key enabler in all aspects of the food industries, which now rely on sampling. We create a self-learning robot-based bin picking solution integrating new grasping tech from CEA and KUKA and hyperspectral visual quality inspection technology from SIEMENS. The combination of a versatile, adaptive grasping device and advanced vision algorithms for fish localization with a modular framework allows groundbreaking fish manipulation and inspection of diverse size, shape, appearance and deformability. Integration in the HRC workspace enables improvements over time in parallel with running operations. Food industry players are welcome to scale up the solution post-project.

Documentation and video

Lead Partner:

Partners

- CEA

- KUKA

- Logomark

- Lda

- Modelo Continente – MCH

- Siemens

- Sonae MC