Woamy: Redefining sustainable packaging with cellulose-based biofoam

Plastic waste remains one of the most pressing global environmental challenges, especially in the packaging industry. Traditional materials, particularly plastic foams, contribute significantly to pollution and environmental harm. Finnish startup Woamy is addressing this challenge with its innovative biofoam technology, offering a sustainable alternative to harmful plastic foams. Founded on over a decade of scientific research, Woamy is on a mission to revolutionise packaging with fully bio-based, biodegradable and recyclable solutions.

We spoke with Susanna Partanen, CEO and Co-founder of Woamy, to explore the startup’s journey, its impact-driven approach, and the role of female leadership in manufacturing.

Turning research into scalable impact

Woamy’s origins lie in a foam wood research project conducted at Aalto University, where Woamy’s founders were part of developing the novel biofoam technology. Recognising its potential to replace fossil-based plastic foams, they founded the company to bridge the gap between research and real-world application.

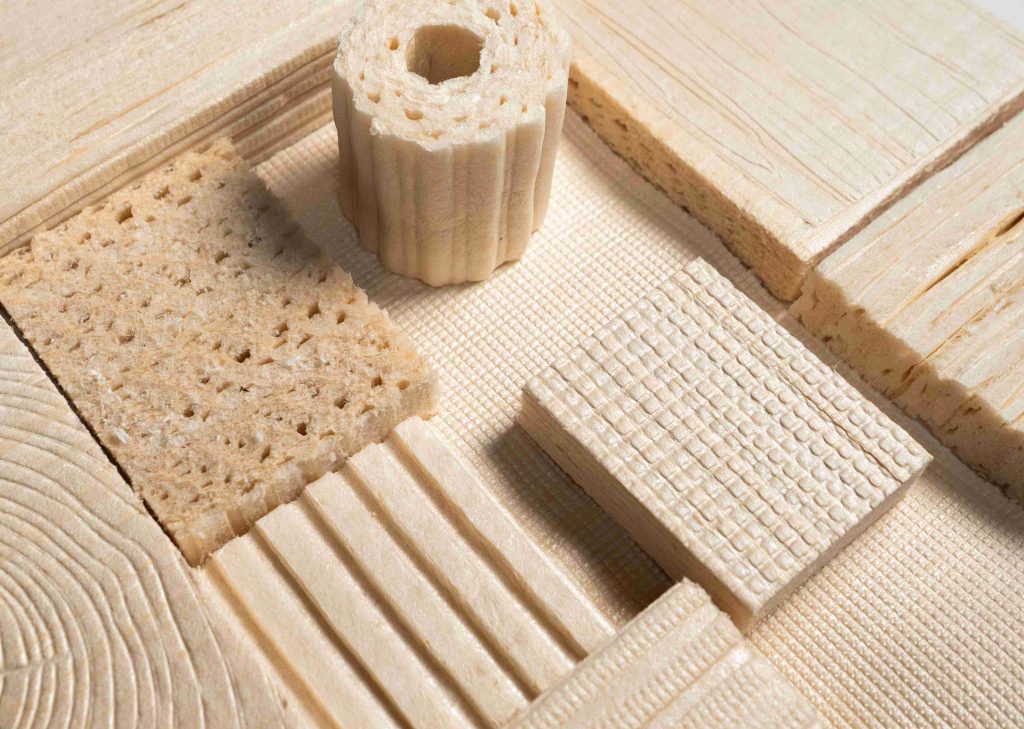

Photo credit: Júli Moon

We founded the company, building on years of research, aiming to scale production and provide a real alternative to plastic foams. Our goal is to transform the industry, starting from the Nordics and Europe, and eventually expanding globally, particularly in regions facing significant plastic waste challenges and inadequate recycling systems.

Susanna Partanen, CEO and Co-founder of Woamy

Woamy’s material offers a drop-in replacement for conventional foams, meaning packaging converters can integrate it into their existing processes without significant changes. This scalability is crucial for ensuring widespread adoption and accelerating the transition to fully circular packaging solutions.

Sustainability without compromise

One of the key challenges in sustainable packaging is balancing environmental responsibility with performance. Many eco-friendly alternatives lack the durability or protective qualities needed for real-world applications.

“Our biofoam is fully biodegradable and recyclable with cardboard, ensuring a truly circular solution,” Susanna continues. “Unlike some alternatives that still contain traces of plastic, our material contains no harmful chemicals or microplastics—so even if it ends up in nature, it won’t cause long-term harm.”

Beyond reducing plastic waste, Woamy’s solution helps manufacturers lower CO2 emissions and meet increasingly stringent regulations on fossil-based materials. As more companies commit to plastic-free packaging, the demand for scalable, high-performance solutions like Woamy’s is growing.

Collaboration for a sustainable future

Bringing sustainable innovations to market at scale requires strong partnerships. Woamy is collaborating with companies eager to embrace sustainable packaging, leveraging support from programmes like EIT Manufacturing’s investment initiatives. This backing helps accelerate product refinement, scale production, and connect with industry leaders committed to reducing plastic waste. Additionally, Woamy has secured investments from corporate venture funds, EIT Manufacturing, and other active investors who share the company’s vision.

“All our investors are committed to bringing our technology to market quickly, providing technical, commercial and fundraising support to accelerate our growth,” Susanna notes. With the previous funding round, Woamy demonstrated the scalability of its technology, significantly increased production capacity, and advanced product development through R&D funding from Business Finland and the EIC Pathfinder for the Archibiofoam project. Now, this new funding round will enable Woamy to accelerate commercial traction and lay the groundwork for scaling to a commercial factory to meet the growing demand for eco-friendly protective packaging.

Championing female leadership in manufacturing

As a female-led company in the traditionally male-dominated manufacturing sector, Woamy is also breaking barriers beyond sustainability. “There are still fewer female-led startups in tech and deep tech, but that is changing. At Woamy, we have two female founders, along with women in board and advisory roles, working alongside our diverse leadership team. It’s not only about having women onboard—it’s about building strong companies through diversity and collaboration.”

Initiatives such as Women TechEU are helping drive this change, supporting female-led ventures and encouraging more women to step into leadership roles. For Woamy, this diversity isn’t just about representation – it’s about reshaping the industry.

We’re proving that a female-led team can build a strong, scalable, and impactful company. And we hope to inspire others to do the same.

Susanna Partanen, CEO and Co-founder of Woamy

Woamy’s story exemplifies how innovative startups are driving positive change in sustainable manufacturing. As the company moves forward, it continues to contribute to a circular economy, transforming industries and paving the way for a future without plastic waste.

EIT Manufacturing’s investment is playing a role in accelerating Woamy’s growth, providing not only financial backing but also strategic support and industry connections to scale its impact. This collaboration proves that innovation and investment go hand in hand in shaping the future of sustainable packaging.

Stay tuned for more inspiring stories from companies like Woamy, who are driving industrial transformation with breakthrough innovations!