CERPRO: Revolutionising quality assurance with AI

CERPRO, an innovative startup founded in 2023 in Berlin, is transforming quality assurance in manufacturing through its AI-powered platform. With a mission to establish a new quality standard for the manufacturing of critical components in industries such as aerospace, medical devices and defence, CERPRO tackles the growing challenges of maintaining high-quality standards. These challenges are amplified by increasingly complex supplier networks and predominantly manual, paper-based quality assurance processes. By addressing these issues, CERPRO provides a seamless solution for both Original Equipment Manufacturers (OEMs) and contract manufacturers, paving the way for a more transparent and reliable manufacturing worldwide.

The founders of CERPRO are from southern Germany, the heart of the Germany’s manufacturing industry and bring strong experience in Industry 4.0, software development and data strategies. They have worked in leading industrial companies as well as prestigious consulting firms like Roland Berger and Ernst & Young (EY). After years of working in consulting, the founders saw the need for a technological solution to automate and improve quality assurance processes in manufacturing.

The Challenge: Manual and time-consuming quality assurance

Quality assurance (QA) in manufacturing remains a largely manual and time-consuming process, creating inefficiencies for both OEMs and contract manufacturers. OEMs often rely on untransparent and outdated QA workflows, where data exchange with suppliers happens via email and technical drawings remain the primary reference, despite the availability of 3D models. On the other hand, contract manufacturers face time-consuming, error-prone documentation processes, non-standardised test requirements and a lack of integration into their customers’ QA systems. These challenges highlight the urgent need for a platform where both can work together to maintain high safety and compliance standards.

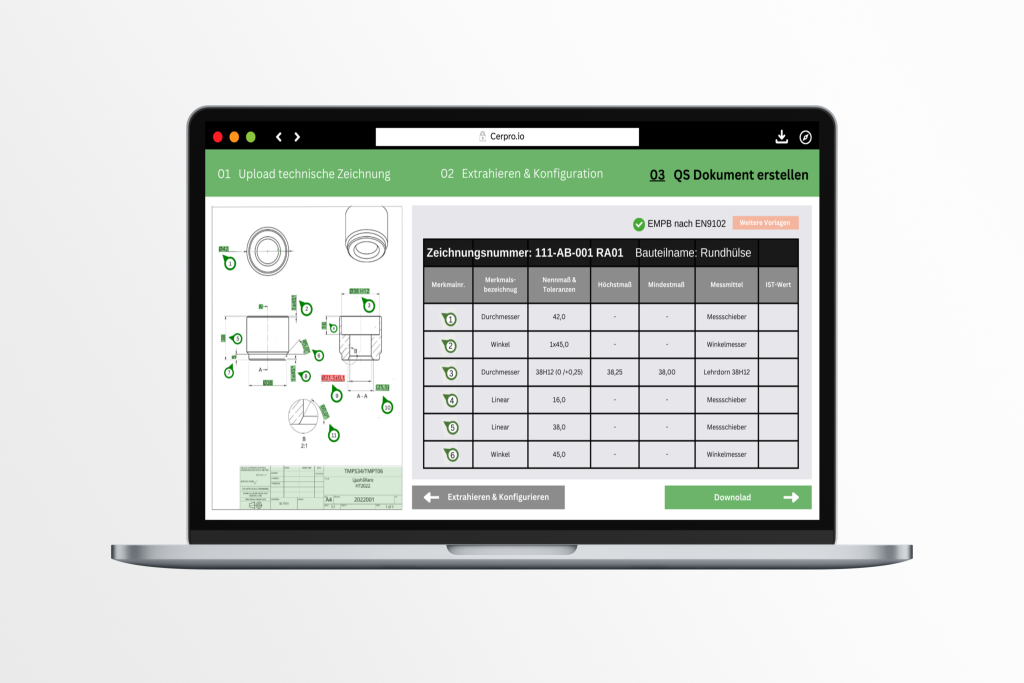

CERPRO’s first product, Quali Spec, marks the initial step in this direction by addressing the pain points faced by contract manufacturers at the start of their quality assurance process. The software leverages artificial intelligence to extract critical features from technical drawings, enabling quality assurance in just minutes instead of hours. By eliminating manual tasks such as feasibility analysis, ballooning and the creation of quality documents, CERPRO’s solution already significantly reduces the time and costs associated with quality inspections for numerous contract manufacturers.

CERPRO’s technology is built for industries that produce small quantities and have complex manufacturing processes, where quality checks are still done mostly by hand. This includes areas like aerospace, defence and medical devices, where a mistake can be very expensive or even life-threatening. “For instance, if an airplane part doesn’t meet the quality requirements, it could have serious consequences,” Henrik Pitz, Co-Founder and COO of CERPRO, explains.

CERPRO solution allows to concentrate on quality assurance, while taking care of the tedious tasks

The Vision: Building a unified quality platform powered by AI

CERPRO envisions a centralised, cloud-based platform that bridges the gap between OEMs and contract manufacturers, fostering seamless collaboration and a unified quality standard across the supply chain. This platform will serve as the single source of truth for quality documents, enabling efficient teamwork and ensuring compliance for both parties.

For OEMs, all quality data will be stored in one place, making it easy to track, share and follow a unified process. With the power of CERPRO’s AI, quality predictions will become possible, streamlining workflows and reducing errors. For contract manufacturers, the platform will provide digital drawings with all necessary production information, simplify data entry and order tracking, and integrate shop floor and top floor systems to ensure smooth operations. “Together, this vision promises to transform quality assurance into a faster, more collaborative and more reliable process,” Frederik Frei, Co-Founder and CEO of CERPRO, describes.

Together, this vision promises to transform quality assurance into a faster, more collaborative and more reliable process.

Frederik Frei, Co-Founder and CEO of CERPRO

The Venture Building Programme: Supporting CERPRO’s growth

CERPRO’s journey has greatly benefited from participating in the Venture Building Programme organised by EIT Manufacturing. This initiative provided invaluable mentorship, networking opportunities and funding, enabling the company to further develop its technology and business model. Sascha Müller, Co-Founder and CTO of CERPRO, states: “The Venture Building Programme has been an important step for us. It connected us with helpful networks and provided support to improve our product.”

The programme also helped CERPRO gain greater visibility and explore growth opportunities in the European market, particularly in industries demanding high precision and quality control. Henrik adds, “Being part of the programme gave us the chance to meet like-minded entrepreneurs and connect with potential partners and customers.”

The Venture Building Programme has been an important step for us. It connected us with helpful networks and provided support to improve our product.

Sascha Müller, Co-Founder and CTO of CERPRO

Next Steps: Scaling and building partnerships

CERPRO’s immediate goal is to refine its product and grow its customer base. Henrik emphasises that building strategic partnerships with OEMs is critical for the company’s success. “We are already in contact with several OEMs and they have shown interest in collaborating to develop the other side of the platform.Their contract manufacturers are already benefiting from our solution, so bringing OEMs into the ecosystem is the next logical step to fully connect the supply chain. One of our key focuses is to launch pilots that link OEMs and contract manufacturers through our platform. This collaboration will be essential to scaling our impact,” he explains.

As the company works to scale, Henrik also advises other entrepreneurs to focus on solving core customer problems. “The biggest lesson we’ve learned is to listen to customers and ensure you’re solving their real pain points. It’s easy to get caught up in building a product you think is perfect, but it’s essential to ensure that it truly addresses what customers need,” he reflects.

One of our key focuses is to launch pilots that link OEMs and contract manufacturers through our platform. This collaboration will be essential to scaling our impact.

Henrik Pitz, Co-Founder and COO of CERPRO

Looking to the future

CERPRO is leading the shift toward automating quality assurance in complex manufacturing industries using its advanced AI technology. Looking ahead, CERPRO’s vision is clear: to set the standard for quality assurance in manufacturing while advancing digital transformation and sustainability in the European market and beyond.

Discover the first digital and intelligent ecosystem for manufacturing

For more information about CERPRO, its services, or collaboration opportunities, visit CERPRO website.

Follow the latest updates from CERPRO on LinkedIn.