DATA4CIRC

DATA4CIRC

The DATA4CIRC project addresses the need for sustainable and competitive manufacturing practices by leveraging advanced digital technologies and data-driven approaches. By focusing on circularity and decarbonisation, the project aims to transform the manufacturing sector, promoting “R-strategies” such as recycling, refurbishing, and reusing materials, while enabling new business opportunities in the circular economy.

Project Objectives: The primary goal of DATA4CIRC is to create an eco-friendlier and more efficient manufacturing ecosystem. To achieve this, the project will develop a comprehensive digital framework that maps and monitors the entire lifecycle of products, enabling data-driven decision-making for sustainable production. The project will deliver the following key solutions:

- Federated Data Spaces: Secure data-sharing platforms built on a zero-trust model, ensuring safe and reliable data exchange within value chains.

- Digital Models for Circular Value Chains and Products: Lifecycle simulation tools to evaluate and improve sustainability across entire value chains.

- Digital Product Passport (DPP): A system to track products and collect lifecycle data, enhancing traceability and transparency.

- AI-Assisted Life Cycle Assessment (LCA) Tools: Advanced tools to assess and predict environmental impacts, using artificial intelligence.

- Ontologies and Semantic Models: User-friendly interfaces and standards to ensure interoperability and accessibility.

The developed solutions will be piloted in three key sectors—electronics, plastics, and automotive—to optimize their functionality before commercialisation. A strong emphasis will be placed on social innovation, including workforce training to ensure seamless adoption of these tools.

DATA4CIRC prioritizes user needs and experiences, ensuring inclusivity and accessibility in its solutions. By addressing both technological and human factors, the project will empower manufacturers to achieve their environmental goals while enhancing competitiveness.

The project’s outcomes will revolutionise recycling, refurbishing, and recovery processes, enabling manufacturers to meet sustainability targets and unlock growth opportunities in a decarbonised economy.

Project Consortium

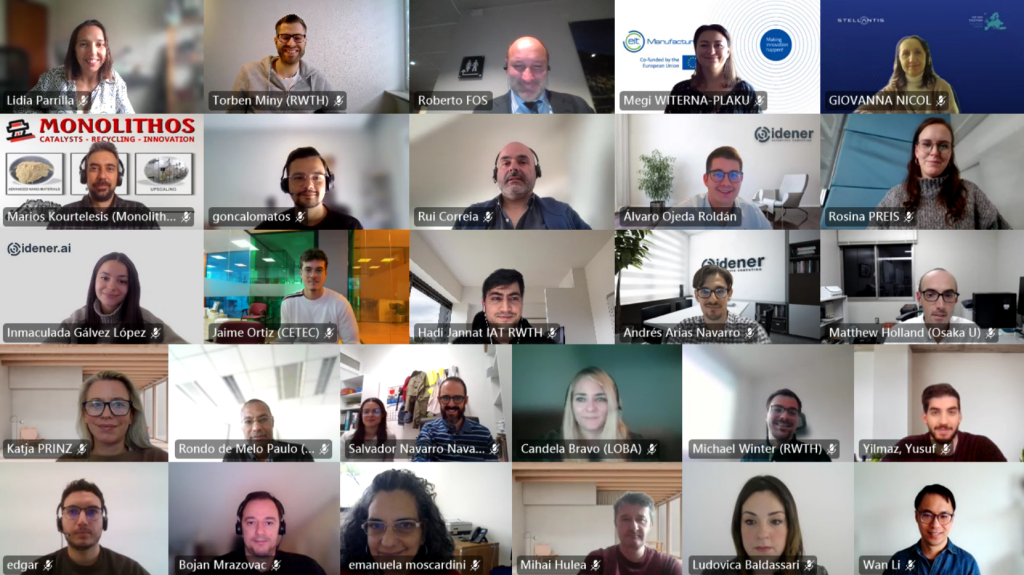

Kick off meeting with all the project partners

DATA4CIRC brings together 13 participants from 8 countries, creating a multidisciplinary team that includes research and technology organizations (RTOs), universities, small and medium enterprises (SMEs), non-profit organisations (NPOs), and a large industry player. The consortium includes:

- IDENER Research & Development Aie (Coordinator) – Spain

- Rheinisch-Westfaelische Technische Hochschule Aachen (RWTH) – Germany

- NTT Data Romania Sa – RomaniaFOS – Italy

- Eco Recycling Societa A Responsabilita Limitata (ECO) – Italy

- Asociacion Empresarial De Investigacion Centro Tecnologico Del Calzado Y Del Plastico De La Region De Murcia (CETEC) – Spain

- Green World Compounding Sl (GWC) – Spain

- Monolithos Katalites Ke Anakiklosi Etaireia Periorismenis Evthinis (MONO) – Greece

- Centro Ricerche Fiat Scpa (CRF) – Italy

- EIT Manufacturing East GmbH (EITM) – Austria

- Globaz, S.A. (LOBA) – Portugal

- DIN Deutsches Institut Fuer Normung Ev (DIN) – Germany

- Osaka University – Japan